Cokes

Coke is a synthetic raw material used for producing carbon in combination with binding agents (or binders). There are different kinds of coke, e.g. petroleum coke, pitch coke, metallurgical coke, carbon black, needle coke.

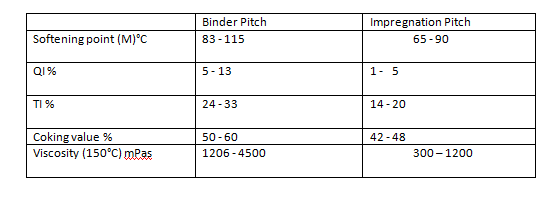

For a summary of their characteristic date click here.

Different kind of cokes

Petroleum coke PICTURE

Petroleum coke, as far as quantity is concerned, is the most important raw material, and it is formed in a wide range of structures – from highly anisotropic needle coke to nearly isotropic fluid coke. The highly anisotropic needle coke, due to its structure, is indispensable for the manufacture of high-performance electrodes used in electric arc furnaces, where a very high degree of electrical, mechanical and thermal load-bearing capacity is required. For fine-grained graphites, it plays a less significant role, since its highly ordered structure is destroyed by the crushing and miling operations which are used to obtain a powder with the required low grain size. Petroleum coke is almost exclusisively produced by the delayed coking process, which is a mild slow carbonising procedure of crude oil distillation residues.

Greek coke

When petroleum coke is produced by the delayed coking process which is a mild slow carbonising procedure of crude oil distillation residues, it is called green or raw coke. It still contains considerable amounts (approximately 5 to 12%) of aliphatic constituents, hydrogen and heteroelements; which, at elevated temperatures, are set free as volatile matter. This mass loss leads to high shrinkage of the coke and to the formation of pores and cracks, which generally rules out of direct processing of green coke to shaped artefacts. Therefore, they are mixed with either a coal tar pitch of relatively low viscosity or an anthracene-oil refluxed pitch or a crude tar. The green coke is calcined at 1200 to 1400 C mainly in rotating kilns or hearths. During this treatment the volatile constituents of the coke are reduced to less than 0.5%.

Pitch coke

Pitch coke is manufactured from thermally treated coal tar pitch either by using the delayed coking process, or by means of conventional coking procedures. Its structure is less ordered than petroleum coke, but its strength and hardness are higher.

Application of binder pitch

Aluminium industry: prebaked anodes, soederberg anodes, ramming paste, cathodes

Electric Steel Industry: graphite electrodes

Speciality Application: clay pigeons, refractory bricks, brushes, specialy graphite, carbon electrodes, fibres, carbon/carbon composites, calcium carbide, arc carbon (welding), high temp. processing of metals, glass and ceramics, mechan. Graphite.

Function of binder pitch

1. Plastifies the green mix, thus permitting the body to be shaped (by extrusion, moulding, vibration…);

2. Acts as a binder in the green body: glues the mix dry components;

3. Acts as a binder in the baked artefact as “pitch coke” and connects the dry components definitively.

4. The amounts of pitch required depends on the property of filler material and grain size. Pitch Characterization

Pitch Characterization

Typical properties

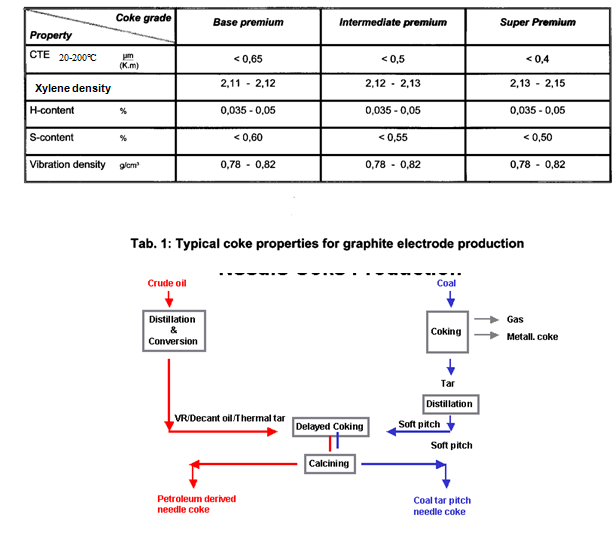

Standard properties of coke

Different kind of fillers

Carbon black PICTURE

In contrast to the soot formed under normal combustion conditions, industrial carbon blacks, with maximum particle diameters of several nanometres, are produced on a large scale at considerably higher temperatures. They are practically free from physiologically hazardous polycyclic aromatic hydrocarbons (PAHs). These blacks have a very fine particle size, which makes them unsuitable for processing directly into solid shapes. Therefore, they are mixed with either a coal tar pitch of relatively low viscosity or an anthracene-oil refluxed pitch or a crude tar of high viscosity or a mixture of these substances to give a plastic material which is formed by tamping or extruding into bale or noodle-shaped bodies that can be processed more easily. These petroleum artefacts are baked and calcined at temperatures between 1200 and 1400 C. The material thus produced is called carbon black or lamp black coke and may be used the same way as petroleum, metallurgical, green, or pitch coke. This relatively expensive manufacture of a raw material is justified by some very special properties of the product obtained. The very low microcrystalline order of the carbon black is not significantly improved even by graphitisation. Especially the crystalline growth along the a-axis remains limited, so that the graphitised carbon black coke retains its microcrystallinity already set by the initial particle size of the carbon black. This results in a very consistent, relatively high electrical resistance, and high hardness compared with other graphite material. These properties make such raw material well suited for electric carbon brushes and for special mechanical applications.

Needle coke

Needle coke is the commonly used term for a special type of coke with extremely high graphitizability resulting from a strong preferred parallel orientation of its turbostratic layer structure and a particular physical shape of the grains.

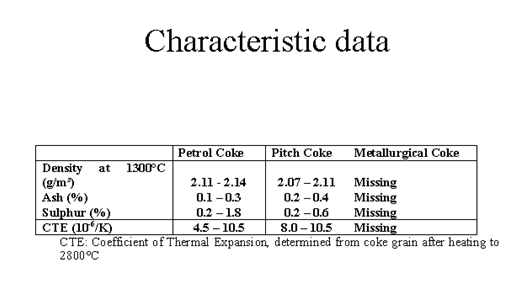

Click here for the production process of needle coke.

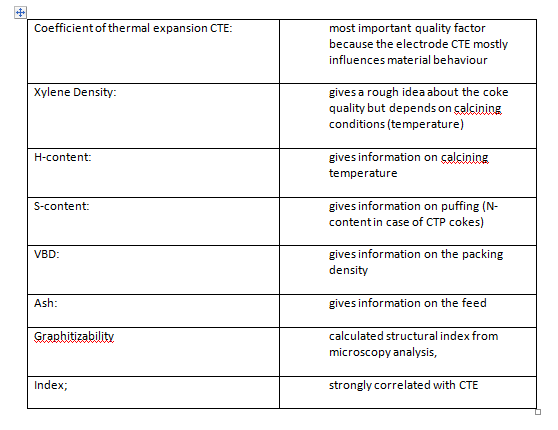

Typical needle coke properties.